OVERVIEW

The HCS series magnetostrictive liquid level transmitter is a brand new liquid level measuring instrument developed by our factory based on the introduction of key components and magnetostrictive technology from MTS company in the United States.

FEATURES

- High measurement accuracy, up to 0.1% FS

- Large measurement range

- On site indication and signal remote transmission compatibility

STRUCTURE AND MEASUREMENT PRINCIPLE

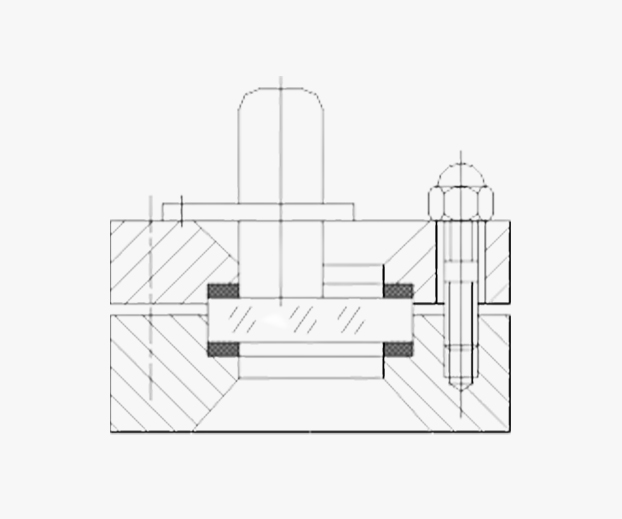

The liquid level gauge consists of main components such as a liquid level sensor, transmitter, and on-site indicator.

The sensor consists of a waveguide, magnetostrictive metal wire, and magnetic float.

When the electric pulse transmitter applies (seeks) an electric pulse to the magnetostrictive wire inside the waveguide, a pulsed magnetic field is generated around the metal wire, which is added to the moving float magnetic field vector to form a spiral magnetic field. Under the action of a spiral magnetic field, the magnetostrictive wire twists (Wiedemann effect) and generates tension pulses. These pulses are transmitted back to the tension sensor at a fixed speed and converted into electrical pulses. The position of the float is determined by the time difference between the issuance of the search pulse and the receipt of the tension pulse.

TECHNICAL PARAMETER

- Measurement range H: 500~6000mm

- Measurement accuracy: ± 0.1% FS

- Work pressure: ≤ 2.5MPa

- Medium temperature: -40~150 º C

- Environmental temperature: -40~60 º C

- Medium density: ≥ 0.36g/cm3

- Working voltage: 24V DC

- Output signal: 4~20mA.DC

- ATEX: d Ⅱ BT4. ib Ⅱ BT4

- Protection level: IP66

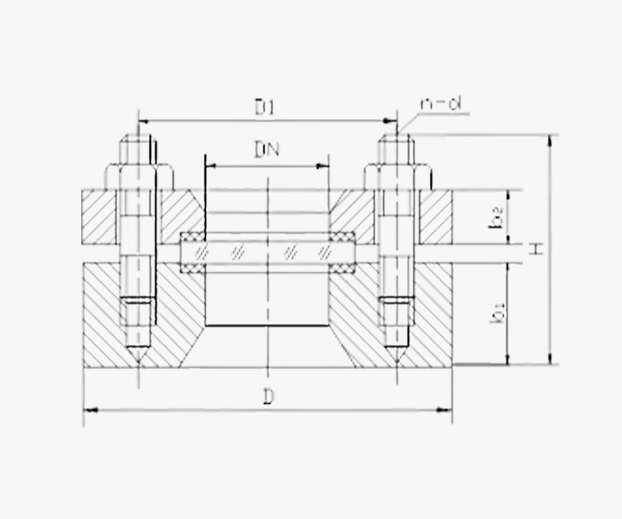

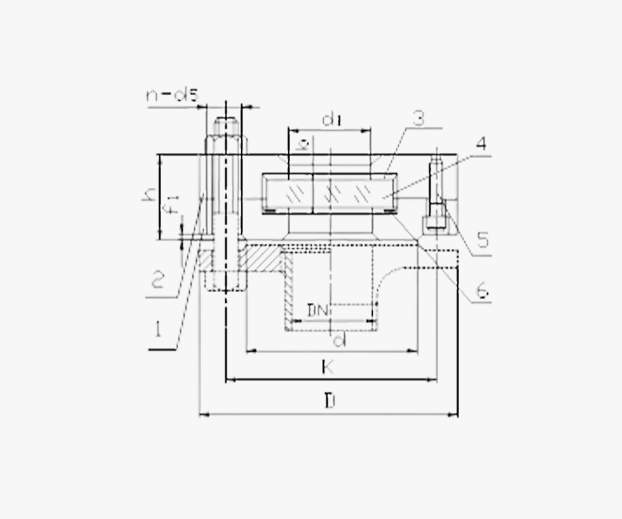

- Connection flange: Specification: DN100, 125, 150 (optional)

- Standards: JB/T81-94, HG20593-97

- Wetting material: 1Cr18Ni9Ti, Ti. 304, 316, 316L

- Installation method: container top installation, bypass pipe installation, pool wall bracket installation