OVERVIEW

The HQK-71 series floating ball liquid level controller is a top mounted liquid level measuring instrument for containers, especially ideal for measuring the liquid level of underground and semi underground storage tanks.

Tested media: water, industrial wastewater, various oil products, and liquid media such as acids and alkalis.

STRUCTURE AND MEASUREMENT PRINCIPLE

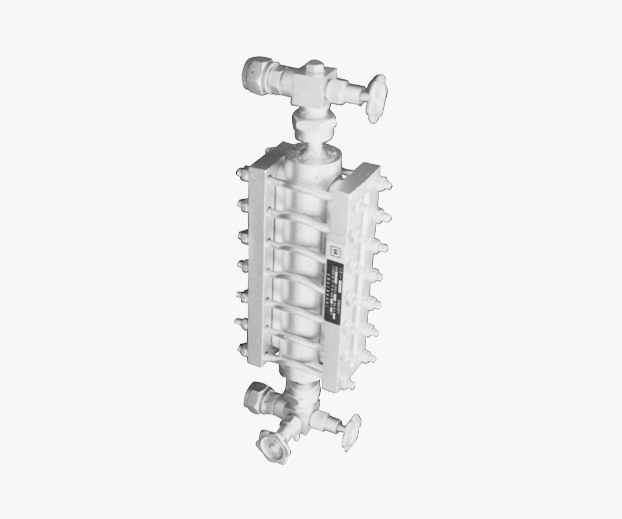

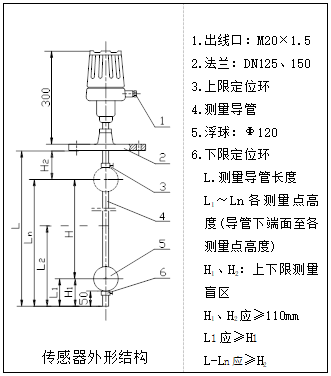

The HQK-71 series float level controller consists of two parts: a level sensor and a display controller.

The liquid level sensor consists of magnetic float, measuring conduit, connecting flange (or thread or support plate), and junction box and other components.

The float floats up and down along the conduit with the change of liquid level, and through magnetic coupling, the corresponding reed switch in the conduit absorbs and outputs the switch signal or resistance signal at the corresponding position. The switch signal is used for remote alarm or liquid level control; The resistance signal is converted to output a 4-20mA signal for remote liquid level display.

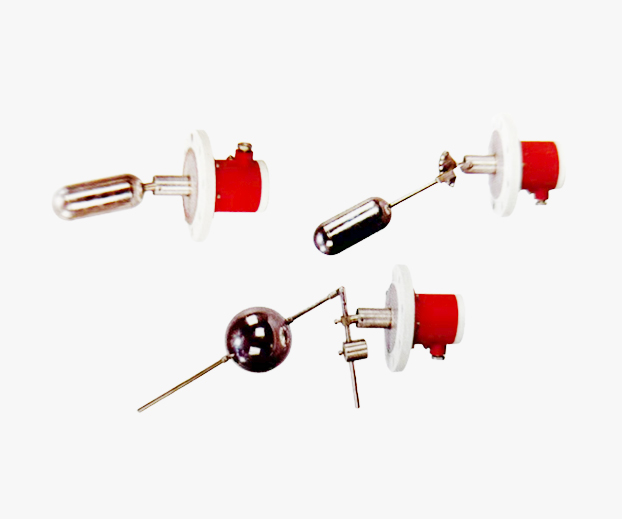

TYPES OF SENSORS

According to the nature of output signal, sensors can be divided into four types:

- High power reed switch signal direct output type.

MODEL: HQK-71G - Low power reed switch signal output type.

MODEL: HQK-71K - Analog output type (4-20mA. DC)

MODEL: HQK-71M - Multi floating ball type: model HQK-71DQ

TECHNICAL PARAMETER

- Measurement range H: ≤ 6000mm

- Measurement error: ± 5mm

- Capacity of reed switch: High power transistor: 220V AC, 2A; Low power transistor: 24V DC, 0.3A;

- Work pressure: ≤ 4.0MPa

- Medium temperature: -20~120 º C (special design when>120 º C)

- Medium density: ≥ 0.45g/cm3

- Medium viscosity: ≤ 1.25st

- Wetting material: 1Cr18Ni9Ti, 316, PVC plastic

- Explosion proof grade: dIIBT4

- Protection level: IP66

- Connection method: Flanges: DN125, 150 (optional); Standard: PN0.6~2.5, JB/T81-94; PN4.0,JB/T82.1-94; Thread: M72 × 4 (floating ball outer diameter Φ 65); Support plate: 150 × 60 (mm), used for pool wall installation.

INSTALLATION METHOD

Top loading of containers

Installation of container bypass pipe

Installation of pool wall support plate

When the measured liquid level fluctuates greatly, anti wave tubes can be installed outside the float and conduit.

Note: In the control circuit, the manual control part is not shown. In practical applications, manual control buttons and manual/automatic switch should be added. When the manual control liquid level is normal, it can be switched to automatic control mode.