OVERVIEW

The HTI series static pressure level gauge is a level instrument that uses the principle of static pressure to continuously measure the depth of liquid.

The static pressure level gauge has a series of characteristics such as a large measurement range, high accuracy, wide range of applicable media, strong corrosion resistance, and no movable parts.

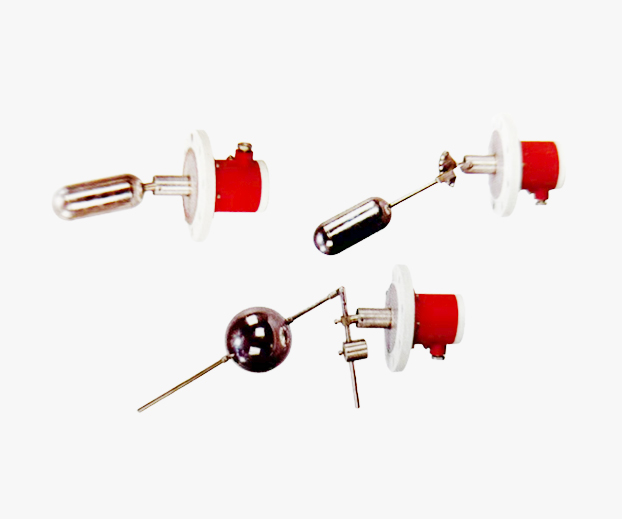

There are two types of static pressure liquid level scoring cable insertion and protective tube insertion

STRUCTURE AND MEASUREMENT PRINCIPLE

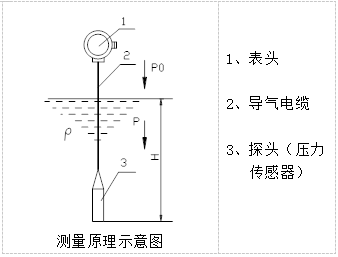

The HTI series static pressure level gauge consists of components such as pressure sensors, air guide cables, and converters.

Static pressure level gauge determines the liquid level height by measuring the static pressure of the liquid column generated by the liquid. The static pressure of a liquid is represented by the following equation: P=P0+ρ gH

In the formula: P: static pressure at the measuring point (pressure sensor sensing hole)

P0: Atmospheric pressure at the upper part of the liquid surface

ρ: Medium density

g: Gravitational acceleration

H: Liquid level height (distance from pressure sensing hole to liquid level)

Since ρ and g are known constants, when р 0 is constant, the static pressure P is only linearly related to the liquid level height H. Therefore, the magnitude of the measured P value can determine the H value.

When the liquid level height H changes, the static pressure P at the measuring point will also change accordingly. This changing static pressure is applied to the pressure sensor, and after P/V and V/I conversion, it outputs a 4-20mA DC standard signal that is linearly related to the liquid level height H.

When the atmospheric pressure P0 at the upper part of the liquid level changes, the pressure sensor is affected in the same way as the liquid level changes. To eliminate the influence of P0 changes, a hollow breathable cable is used to introduce the external atmospheric pressure into the other side of the sensor's pressure sensing surface. Thus, measurement errors caused by changes in atmospheric pressure can be eliminated.

TECHNICAL PARAMETER

- Measurement range H: distance between the pressure sensing hole and the upper limit of the liquid level

- Cable insertion type:<50m

- Protective tube insertion type: ≤ 6m

- Measurement accuracy: ± 0.5% FS

- Work pressure: normal pressure

- Medium temperature: -30~80 ℃

- Environmental temperature: -30~55 ℃

- Medium density: ≤ 2.0g/cm3

- Medium viscosity: ≤ 1.25st

- Supply voltage: 24V DC

- Load impedance: ≤ 550 Ω (when powered by 24V DC)

- Output signal: 4-20mA. DC (two-wire system)

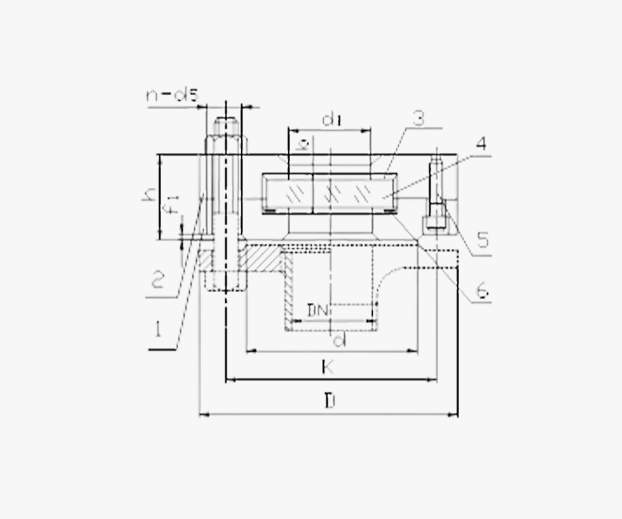

- Connection method: flange or thread

- Flange: DN40, JB/T81-94

- Thread: G1 ½" (external)

- Explosion proof grade: dIIBT4

- Protection level: IP66

- Liquid receiving material:

- Pressure sensing film: ceramic, 316, 316L

- Seals: Nitrile rubber, PTFE, Fluororubber

- Air conducting cable: rubber, PVC or fluorine protective tube

- Inserted protective tube: 1Cr18Ni9Ti, 316, 316L