OVERVIEW

The UFZ-4 simple float level gauge is a pointer type simple float level gauge. It consists of main components such as a buoy, buoy towing cable, guide steel cable, transverse conduit assembly, and ruler plate, heavy hammer, and pointer. The float level gauge uses a float as the measuring element, and the float floats up and down with the rise and fall of the liquid level. The heavy hammer and pointer on the scale plate are synchronously moved in reverse by the float traction cable, and the pointer continuously indicates the height of the liquid level on the scale plate.

The top of the scale plate indicates the zero position of the liquid level, and the bottom indicates the full range of the liquid level.

The float level gauge has a simple structure and can be widely used for continuous measurement of various liquids, as well as high viscosity and corrosive liquids in large and medium-sized storage tanks.

MEASURING PRINCIPLE

The float level gauge operates based on the principle of force balance. Assuming the weight of the buoy is G, the weight of the heavy hammer and pointer is W, the buoyancy of the liquid on the buoy is F, and the friction coefficient of the system is f. When the buoy is submerged in a certain position of the liquid and stationary, these forces are in equilibrium, that is, G-F-W ± f=0. When the liquid level rises, the buoyancy F increases, the system loses balance, and the heavy hammer and pointer move downwards; When the liquid level drops, the heavy hammer and pointer rise, continuously indicating the height of the liquid level.

Series varieties and external structure

FEATURES

- The series of varieties and appearance structure displays indicate the liquid level in red, and the upper white area is the liquid free part (liquid red and gas white). The liquid level display is intuitive and eye-catching, with good night lighting effect.

- The liquid level measurement range is large, not limited by container specifications, shapes, and installation positions, and there are no blind spots in the entire measurement process.

- The liquid level display is completely isolated from the measured medium, ensuring safety and reliability.

- The liquid receiving part is made of different materials and can be used for measuring the liquid level of various corrosive media.

- The measurement of liquid levels in high temperature, high pressure, toxic, harmful, flammable and explosive media has strong adaptability.

TECHNICAL PARAMETER

- Measurement range: H ≤ 25m;

- Indication error: ≤± 20mm;

- Work pressure: normal pressure;

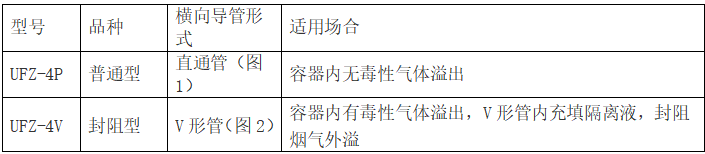

- Medium temperature:

UFZ-4P type: ≤ 200 ℃;

UFZ-4V type: The medium temperature should be lower than the boiling point temperature of the isolation liquid filled in the V-shaped tube - Medium density: ≥ 0.6g/cm3;

- Horizontal conduit and container connection method: flange connection; Specifications: DN50, DN200 (optional), PN1.0,JB/T81-94 Or make according to the flange specifications and standards provided by the user, please specify when ordering.

- Float specification: φ 240 x height 160 (mm);

Diameter of guide rings on both sides of the buoy: φ 32 × 2 (mm);

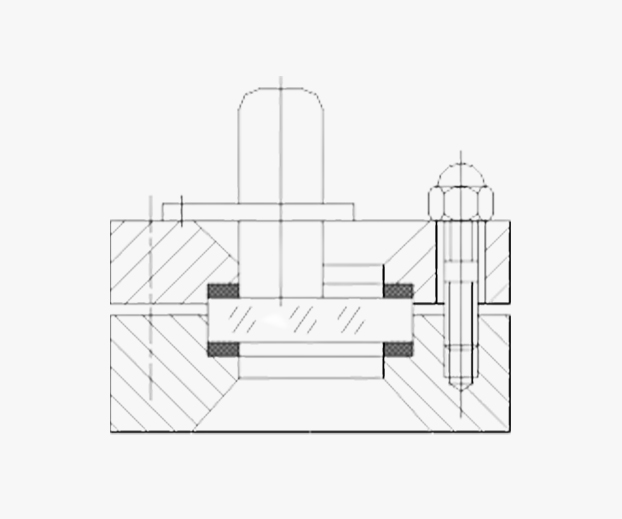

The center distance of the guide ring is 270mm, as shown in Figure 3 - Liquid receiving material: various grades of stainless steel. (Select by liquid chemical properties)