OVERVIEW

MEASURING PRINCIPLE

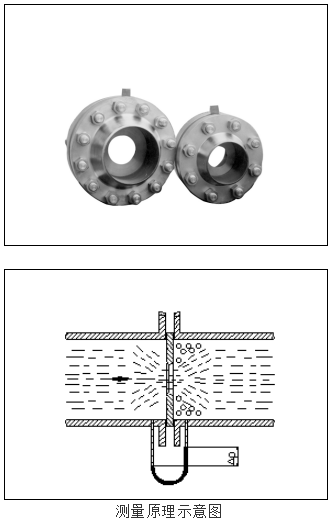

When the fluid filled in the pipeline flows through the orifice plate, local contraction occurs, the flow bundle is concentrated, the flow velocity increases, and the static pressure decreases. Therefore, a static pressure difference is generated before and after the orifice plate, which has a certain functional relationship with the flow rate. The larger the flow rate, the greater the pressure difference.

The differential pressure signal is transmitted to the differential pressure transmitter through a pressure conduit, converted into a 4-20mA.DC standard signal, and displayed on the flow meter to show the instantaneous and cumulative flow inside the pipeline.

Pressing method

There are three common pressure measurement methods for orifice plate throttling devices:

- Corner joint pressure measurement (ring chamber, drilling hole).

- Apply pressure to the flange.

- D-D/2 radial distance pressure measurement.

TECHNICAL PARAMETER