OVERVIEW

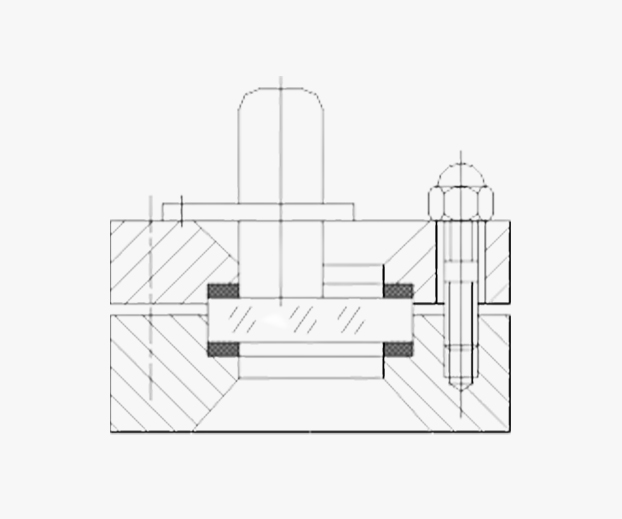

The orifice plate throttling device is tightly combined with a differential pressure transmitter through a three valve group to form an integrated orifice plate flowmeter.

Integrated orifice flowmeter can be widely used in industries such as petroleum, chemical, natural gas, metallurgy, power, and pharmaceuticals for continuous measurement of volume flow or mass flow of various liquids, gases, natural gas, and steam.

FEATURES

- Integrated structure, good completeness

- High measurement accuracy and wide range ratio

- The pressure difference can reach 30mmH2O

- High temperature and high pressure resistance, strong corrosion resistance, suitable for various working conditions

- Adapt to a wide range of pipeline diameters

- Easy to install and use

- On site digital display and signal remote transmission compatibility

TECHNICAL PARAMETER

- Caliber: DN25~DN1000 (mm)

- Accuracy: ± 1% FS

- Range ratio: standard 1:13, expansion 1:20, 30, 40

- Work pressure: ≤ 42.0MPa

- Medium temperature: -40 ℃~450 ℃

- Medium viscosity ≤ 30CP (equivalent to heavy oil)

- β value: 0.2-0.8

- Connection method: flange or clamp type

- Flange standard:

PN2.0~26.0,DN15~600,HG20618-97

PN2.0~5.0, DN650~1000, HG20623-97

PN11.0~15.0, DN650~900, HG20623-97

PN32.0~42.0, DN15~300, HG20618-97

It can also be manufactured according to the flange standards provided by the user - Material: Main body, orifice plate, pressure tapping tube, three valve group, all made of stainless steel; Straight pipe section and connecting flange, made of carbon steel or stainless steel.

- Installation method: horizontal or vertical

- Differential pressure transmitter:

- Output: 4-20mA.DC

- Power supply: 24V DC

- Explosion proof rating: d Ⅱ CT5.6, ia Ⅱ CT4-6

- Protection level: IP67

- Header: Blind meter and digital meter