OVERVIEW

LQH-100、 The 200 series maglev level switch can be widely used for fixed-point alarm or control of various liquid levels or interfaces in fields such as petroleum, refining, chemical, pharmaceutical, food, and power. The structure and measurement principle of the maglev liquid level switch consists of a cylinder, a floating ball (cylinder) component, a conversion mechanism, and other components, which are connected to the container through flanges or threads. The measuring components of liquid level switches come in two forms: floating balls and floats, which work using the principle of buoyancy and magnetic coupling technology. Float ball type: When the liquid level rises or falls, the float ball drives the magnetic element at the top of the connecting rod to enter or leave the magnetic field of the conversion mechanism, causing the switch to act and output a switch signal. Similarly, when the liquid level drops, the switch contacts switch to another state.

Due to the use of springs as balancing elements, the effective weight of the float can be increased, thereby improving the pressure resistance level of the instrument.

STRUCTURE CHARACTERISTICS

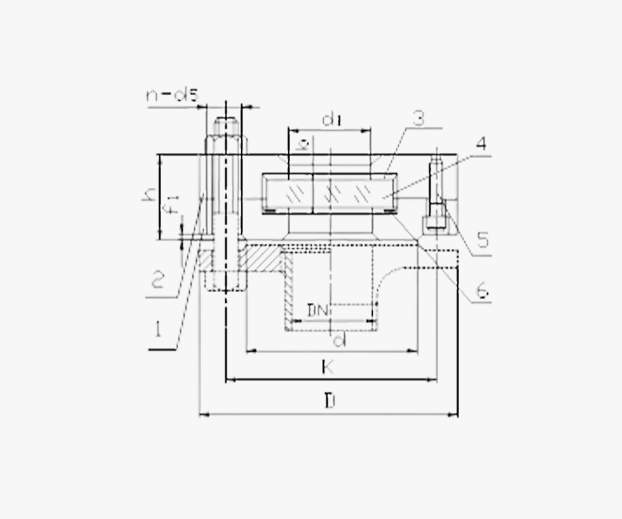

- 100 series example: flange connection on the upper head of the cylinder

- 200 series example: upper head welding type, fully sealed structure.

TECHNICAL PARAMETER

- Output signal: Micro switch, one normally open, one normally closed; Or two normally open and two normally closed (when using both upper and lower limit control, there is no two normally open or two normally closed type)

- Contact capacity: 220V AC, 3A (ordinary, explosion-proof type), 24V DC, 50mA (intrinsic safety type)

- Control error: liquid level ± 4mm, interface ± 6mm

- Work pressure: 4.0, 6.3, 10.0 (MPa)

- Medium temperature: Room temperature type: -20~150 º C; High temperature type: 150~400 º C

- Environmental temperature: -40 º C to 60 º C

- Medium viscosity: ≤ 1St (10-4m2/S)

- Medium density: 0.4-3.0g/cm3(Liquid level)

- Density difference: ≥ 0.16 g/cm3(Liquid level, floating ball type)

- Outlet: M20 × 1.5 (internal)

- Explosion proof grade: d Ⅱ BT1-4, ib Ⅱ BT1-4, ib Ⅱ CT1-4

- Protection level: IP66

- Distribution parameters:

- The supporting pipe length of the main riser is 160mm;

- Indication error: ≤± 20mm;

- Work pressure: ≤ 1.6MPa;

- Medium temperature: ≤ 450 ℃;

- Medium density: ≥ 0.6g/cm3;

- Horizontal conduit and container connection method: flange connection. Flange specifications and standards: DN50, DN200 (optional), PN1.6 flat, JB/T81-94; Other flange specifications and standards can also be selected, please specify when ordering.

- Float specification: φ 240 × 160 (height), mm。 The diameter of the guide rings on both sides of the buoy is φ 32 × 2 (mm). The center distance between the guiding rings on both sides of the buoy is 270mm,

- Liquid receiving material: various grades of stainless steel (selected according to the chemical properties of the liquid).

- Optional auxiliary components: a) MY type liquid level transmitter; b) GB type liquid level alarm; c) VB type liquid level alarm;