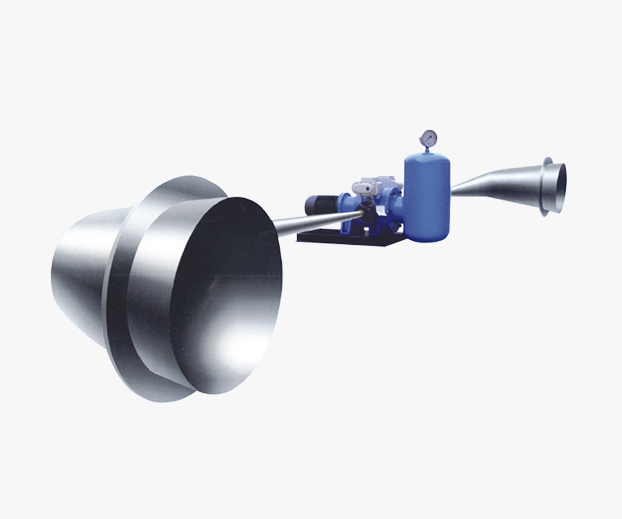

OVERVIEW

The illuminated mirror consists of two parts: the mirror and the mirror light, which can clearly observe the solid-liquid state of the material inside the container.

MIRROR STRUCTURE TYPE

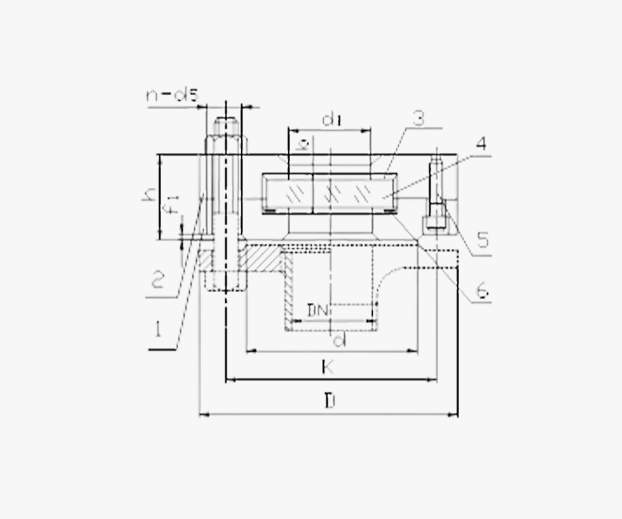

Type A: Model SJD-A Standard Type

Type B: Model SJD-B with flushing hole for flushing the inner optic lens

Type C: Model SJD-C with neck mirror, proposed by the user

D-type: Model SJD-D with neck mirror and flushing hole

Mirror light type

Mirror lights are equipped with cold beam reflective halogen tungsten bulbs.

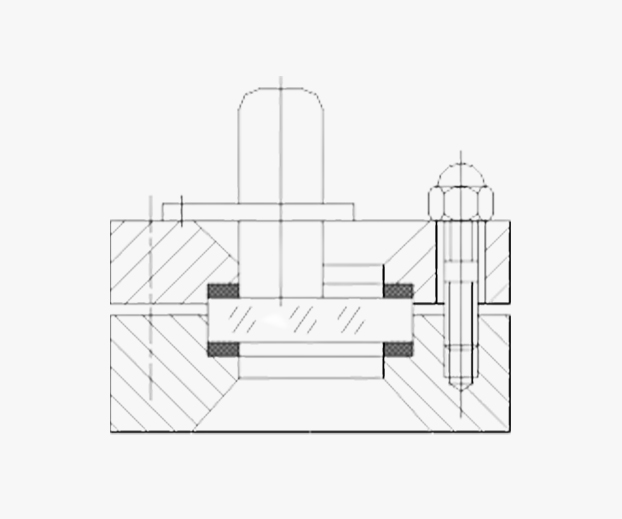

▲ ANTI CORROSION TYPE: CODE F

The mirror light occupies half of the area of the mirror glass, while the other half allows for a glimpse of the interior of the container. The mirror light also comes with a junction box, and the transformer is installed inside the junction box, which can be installed at any position.

There are four specifications for anti-corrosion mirror lights and mirror matching: DN100, 125, 150, and 200.

Anti corrosion mirror lights can be used in environments with corrosive gases, with the following basic parameters:

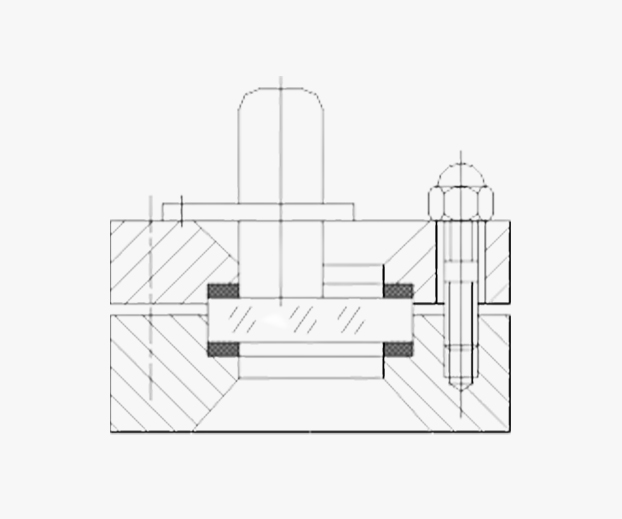

▲ EXPLOSION PROOF TYPE: CODE D

The mirror light occupies most of the area of the mirror glass, and an additional non light mirror needs to be installed inside the container for peering.

There is only one specification for explosion-proof mirror lights, DN100, which can be used for different specifications of mirrors.

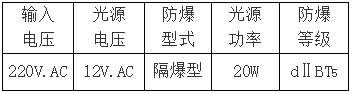

The mirror light is equipped with a transformer and can be used in Zone 1 and Zone 2 of explosive hazardous areas. The basic parameters are as follows:

TECHNICAL PARAMETER

- Work pressure: 0.25, 0.6, 1.0 (MPa)

- Nominal diameter: DN100, 125, 150, 200 (mm)

- Medium temperature: 0-200 ℃

- Sudden temperature change: ≤ 180 ℃

- Mirror glass: tempered borosilicate glass