OVERVIEW

This product is a new generation liquid level measuring instrument specifically developed for enterprises in the petroleum and chemical industries. In the past, liquid level measuring instruments were still limited to single machine liquid level measurement. However, in some enterprises such as petroleum and chemical, the measurement of liquid level in certain containers requires both accuracy and high reliability, as well as reducing the number of openings in containers when multiple machines are installed. When one machine fails, the other machine can still work normally. Thus, an integrated intelligent dual system liquid level measurement device (referred to as the "dual system") was developed and researched. This product has high measurement accuracy, synchronized with liquid level, and is safe and reliable. In addition to simultaneously monitoring the liquid level inside the container, the "dual system" can also monitor the interface of two different media with different weights inside the container as needed.

THE COMPOSITION OF THE 'DUAL SYSTEM'

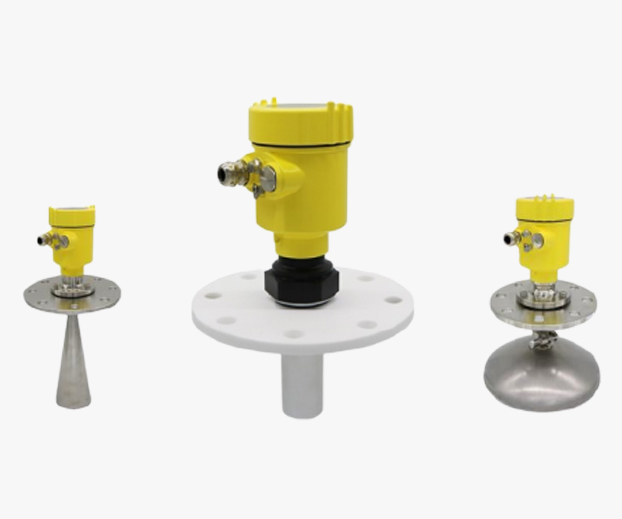

The integrated dual system liquid level measurement device consists of two parts: a host intelligent remote liquid level transmitter and a secondary machine on-site display liquid level gauge. The host is connected to the container flange through a flange to form a connector. The payment machine and the host form a tightly integrated dual system liquid level measurement device through a short connection. The two machines have the same measurement range and upper and lower limit heights, while monitoring changes in the liquid level inside the container and indicating the same liquid level height in different ways, and can transmit liquid level signals remotely.

Dual system features and functions

- The tight combination of "dual systems" simultaneously monitors the same liquid level height, with dual safety, accuracy, and reliability. When one system fails, the other system can still work normally.

- The intelligent remote liquid level transmitter has on-site indication (display) and signal remote transmission functions. Analog transmitter outputs 4-20mA.DC signal; Intelligent transmitter outputs 4-20mA.DC signal with HART protocol.

Intelligent transmitters can also achieve wireless output of liquid level signals to meet the needs of users for remote monitoring and on-site operations.

The on-site display liquid level gauge has direct reading, good far sighting and night lighting effects. According to the needs, a liquid level transmitter or alarm can also be optionally selected. Realize remote transmission of liquid level signals or remote alarm of upper and lower limits of liquid level.

SPECIFICATION

- Measurement range (range): 0-4000mm, made according to requirements.

- Measurement accuracy:

a. Intelligent remote liquid level transmitter: ± 1% FS

b. On site indicator level gauge: ± 10mm - Output format:

3.1 Intelligent remote liquid level transmitter:

a. Analog type (code M): 4-20mA.DC, dual line system.

b. Intelligent type (code Z): 4-20mA.DC with HART protocol.

3.2 On site display level gauge:

a. On site magnetic replica indicates liquid level.

b. If equipped with MY type transmitter (code Y), it can output 4-20mA.DC signal.

c. If equipped with GB or VB type alarm (code B), it can achieve remote alarm of liquid level upper or lower limit signals. - Work pressure: ≤ 10MPa

- Medium temperature: ≤ 350 ℃

- Medium density: ≥ 0.4g/cm3/sup>

- Density difference: ≥ 0.15g/cm3(Measuring specific gravity)

- Medium viscosity: ≤ 0.15pa. S

- Explosion proof rating: EXd Ⅱ BT6, EXd (ia) Ⅱ CT6.

- Wetting material: 1Cr18Ni9Ti or other grades of stainless steel.

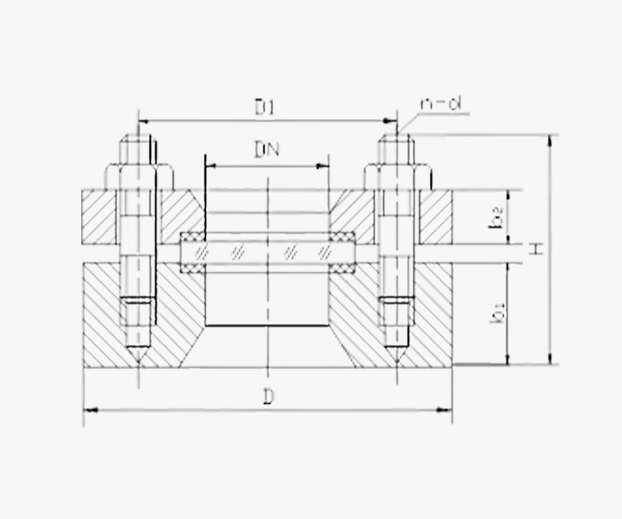

- Specification of flange connecting intelligent remote liquid level transmitter and container:

DN25, DN40, DN50 (optional); Standard DN40

Flange standard: made according to user requirements - Installation method: Side mounted.