OVERVIEW

UCL type heavy hammer level gauge is used to continuously measure the level of powder, granular, and block solid material silos.

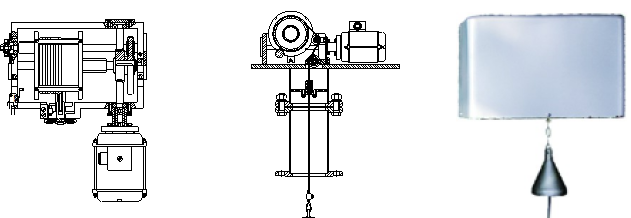

The level gauge consists of a sensor and a control display instrument. The design of the sensor absorbs the advantages of similar products at home and abroad. Its unique structure and transmission method overcome the common problems of many other forms of heavy hammer level gauges in the past, achieving easy installation, smaller body size than other products, more reliable operation, less maintenance, and wider application

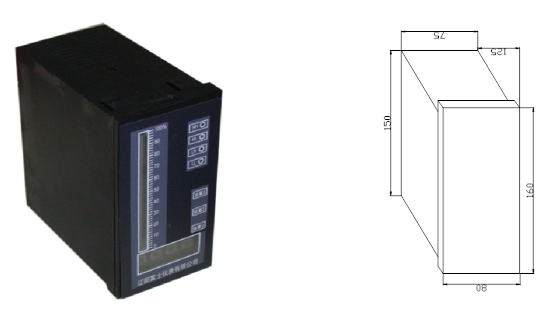

The control display adopts a 16 bit microcontroller, which controls the entire detection process of the sensor through the program and detects its signal for calculation. The material level number is displayed in the display window on the panel, and there is a corresponding 4-20mA analog current signal output. The measurement can be automatically timed or manually measured.

Display controller (see Figure 2 for secondary table), installation method: vertical disc installation.

TECHNICAL PARAMETER

- SENSOR

Measurement range: 0-40m (special specifications can be negotiated)

Measurement accuracy: ± 30mm

Repeatability: ± 1%

Resolution: ± 30mm

Detection speed: 0.15m/s

Storage bin pressure: no pressure

Material temperature: ≤ 600 ℃

Environmental temperature: -30 ℃ to+60 ℃

Measurement strip: Φ2 stainless steel wire rope

Heavy hammer weight: 1kg - Control display instrument

Power supply voltage: 220VAC ± 10% 50Hz ± 1Hz

Power consumption: 5W at rest, 55W during motion

Digital display: 0.00~40..00 (m)

Current output: 4~20mA

Output signal accuracy: ± 0.1%

Timed time: 1-6999 minutes (or as per user request)

Distance from sensor: 0.5km

Weight: 5kg

Dimensions: Rear width 155 x Rear height 80 x Length 135

Hole size: Rear width (150+1) x Rear height (75+1)