OVERVIEW

HJK type instrument is used to detect, alarm and automatically control powdered, granular and block materials in open and closed silos. After long-term operation in industries such as steel, refractory, cement, rubber, chemical fiber, and electricity, ideal results have been achieved and widely used in industrial production.

HJK type instrument is a mechanical instrument with the characteristics of simple structure, high temperature resistance, dust resistance, impact resistance, no complicated electrical circuits, reliable control, and long-term operation

STRUCTURE AND MEASUREMENT PRINCIPLE

The HJK level gauge adopts a swing transmission system. When the detection board is obstructed, the spindle stops and the motor continues to run, causing the release device to trip, resulting in the switch action cutting off the motor power supply, the motor stops working, and a material level signal is issued.

When the material level drops, the resistance of the detection board disappears, the release device resets, the motor resumes operation, a no material signal is issued, and the instrument is in the detection state again. In situations where the material level changes slowly, a timer can be installed inside the instrument to keep the detection of the instrument in an intermittent working state, which can reduce power consumption and wear, and extend the life of the instrument.

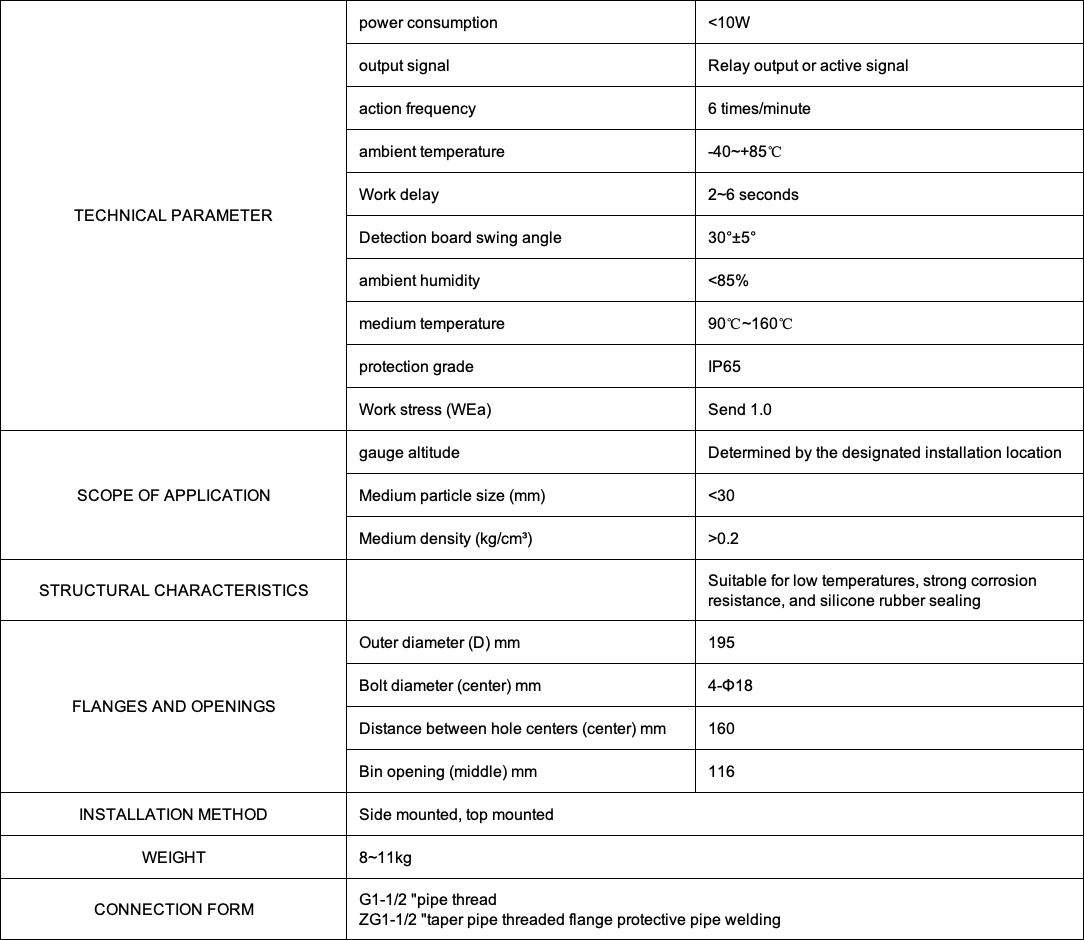

TECHNICAL PARAMETER

TECHNICAL PARAMETER

- Before installation, check the operation of the instrument, connect the power, test run it flexibly, and ensure that the action is correct before installation.

- This instrument is installed horizontally and vertically. When installing horizontally, a protective cover should be added to prevent direct impact of materials. Avoid the discharge port during installation.

- The length of the detection rod should exceed the hanging layer.

- During installation, the outlet and detection board should be facing downwards. (The protective cover has a 180 ° opening facing downwards)

- The length of the protective cover is matched with the length of the instrument, and the installation is inserted into the silo depth according to the design dimensions.

ORDERING INSTRUCTIONS

Explain the tested medium, density, particle size, silo pressure, temperature, silo height, and indicate which switch is installed. (Micro switch or photoelectric switch)

Users can install timers and set detection times according to their needs.

The protective cover and matching FSBJ type flash alarm can be ordered together with the instrument.