OVERVIEW

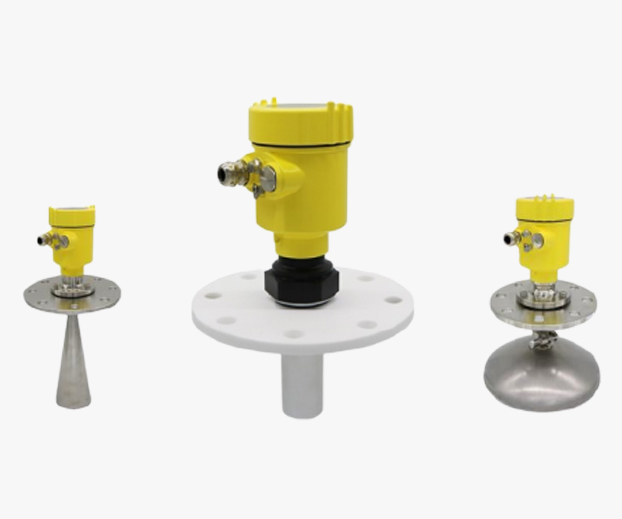

The HJL series resistive rotary level switch is widely used in industrial production processes and storage departments to monitor or control the upper and lower limits of powder and granular materials in open containers.

FEATURES

- The exposed components are made of stainless steel and aluminum alloy, which have the characteristics of corrosion resistance, moisture resistance, and dust prevention.

- The mechanical overload protection device is adopted, which can effectively avoid damage to the motor and reducer caused by improper use or abnormal external forces.

- The blades can be merged and automatically unfolded, making installation easy.

STRUCTURE AND MEASUREMENT PRINCIPLE

The level switch uses a micro motor to drive the detection blades to rotate at a speed of 5-6 revolutions per minute after deceleration. When the material level rises and the rotation of the blades is obstructed, the detection mechanism generates rotational displacement around the main axis. This displacement first causes one micro switch to emit a material signal, and then another micro switch to act, cutting off the power supply of the micro motor and stopping its operation. As long as the material level remains unchanged, this state will be maintained indefinitely.

When the material level drops and the detection blade loses its obstruction, the detection mechanism relies on the spring tension to restore its original state. Firstly, one micro switch is activated to connect the motor power supply, allowing the motor to resume operation. Then, another micro switch is activated to emit a no material signal. As long as there is no material obstructing the rotation of the detection blades, this state will continue to be maintained.

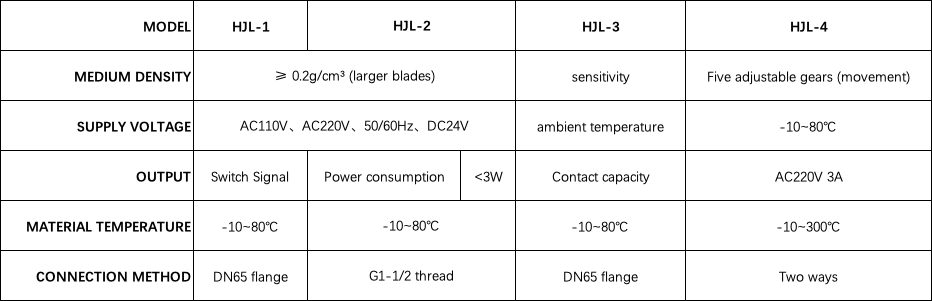

TECHNICAL PARAMETER

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.